Page 13 - Brochure inglese_2022

P. 13

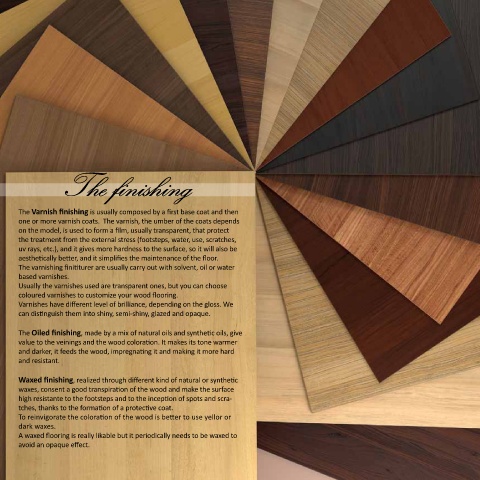

To exalt the natural

aspect of a wooden

flooring, it’s important

to value and choose the

right finishing, manu-

facturing and/or treat-

ments.

The finishing can be var-

sh, oil or wax.

The finishing

The finishing

The Varnish finishing is usually composed by a first base coat and then

one or more varnish coats. The varnish, the umber of the coats depends

on the model, is used to form a film, usually transparent, that protect

the treatment from the external stress (footsteps, water, use, scratches,

uv rays, etc.), and it gives more hardness to the surface, so it will also be

aesthetically better, and it simplifies the maintenance of the floor.

The varnishing finititurer are usually carry out with solvent, oil or water

based varnishes.

Usually the varnishes used are transparent ones, but you can choose

coloured varnishes to customize your wood flooring.

Varnishes have different level of brilliance, depending on the gloss. We

can distinguish them into shiny, semi-shiny, glazed and opaque.

The Oiled finishing, made by a mix of natural oils and synthetic oils, give

value to the veinings and the wood coloration. It makes its tone warmer

and darker, it feeds the wood, impregnating it and making it more hard

and resistant.

Waxed finishing, realized through different kind of natural or synthetic

waxes, consent a good transpiration of the wood and make the surface

high resistante to the footsteps and to the inception of spots and scra-

tches, thanks to the formation of a protective coat.

To reinvigorate the coloration of the wood is better to use yellor or

dark waxes.

A waxed flooring is really likable but it periodically needs to be waxed to

avoid an opaque effect.